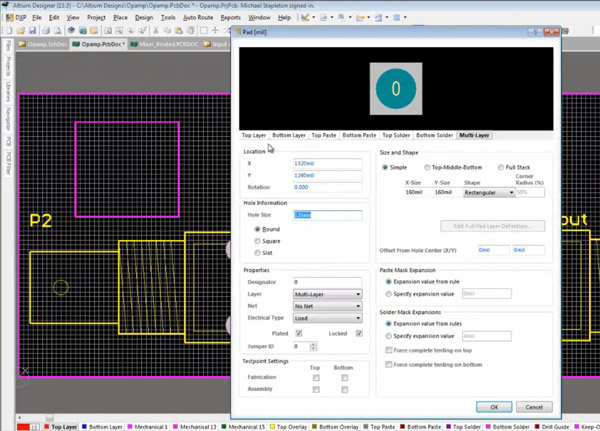

Engraving the printed board “weakens” it and facilitates splitting by bending. The first method consists of the V-cut incision of the printed board via tool. To facilitate the separation of the various prints there are various techniques: In fact, once the panel is built, we should have an easy way to separate the individual circuits without damaging the individual prints. Panel finishingĪs soon as we are satisfied with our placement, we can move on to adding information for the cutting of the various circuits. The placement should be performed in such a way as to minimise the empty space in order not to waste the printout, perhaps by moving or rotating the already placed circuits. Obviously it is necessary to be careful about the process, for example, mirroring means changing the top with the bottom, and if by chance we have particular configurations of the layout of the board this could be reversed with respect to what is expected. So, as soon as we are ready, we can begin to place our circuits using the appropriate “Place > Embedded Board Array/Panelize” command: Only do this when the placement is finished. Panel, but since we have not yet placed all the circuits, we will Have been defined, it will be necessary to establish the shape of our Printed circuit board can have, the minimum and maximum size, the Obviously these parameters depend on the capabilities of our printedĬircuit supplier such as the maximum number of layers that the Will also define all the construction parameters of our circuits. blind, buried routes, etc.)Īll these points into account, we can create our PCB project where we different finishes for the openings, etc.) Same thicknesses of copper and dielectric This will be useful when we need to generate all the necessary files for printing and assembly.Īs mentioned above, to create a single panel with our circuits, various factors must be taken into consideration, and all the circuits must have: As soon as all the circuits that will be part of the panel are ready, we will create a new project that will include our panel. That said, let’s move on to creating a workspace for our example, where we will then add and/or create all the circuits we hope to insert in our panel. Short, a project can be anything that logically forms part of our Each project can contain:Ĭomplete outline of its printed circuit board In this space, the user defines the various projects for each part of the board. To aggregate the various parts of the design Altium uses the concept of workspace. Before startingĪltium Designer provides a complete environment, which helps the designer to build their circuits, from the diagram to the CAM. In our example we will show how it is possible to perform panelling during the routing phase, using Altium Design as EDA. The first step towards the creation of our panel is to use a CAD and ideally, as we say in jargon, an EDA (Electronic Design Automation) that will assist us in the various steps of the design both in the routing phase and in the CAM phase. Later in our article we will examine these aspects in greater detail. Obviously to create a single panel with all our circuits we must take into account different aspects such as the complexity of the circuit we want to create, the total surface area, the minimum dimensions, etc. In this case, it could be worthwhile creating your own panel at home and then having it made by any supplier. It is a different story instead, if for reasons of time, or simply because we are making prototypes as a hobby, we rely on PCB suppliers, who have an online shop and who only provide an interface for the common settings and that do not have ad hoc panelling services for our needs.

The creation of a single panel can be delegated to our supplier of printed circuit boards with the addition of a small surcharge. To overcome these problems, a possible solution is to place all our tests on a single panel, thus paying only once all the fixed costs attributable to the start of production.

This means creating several printed boards and therefore incurring prototyping costs that are greater than making a single printed board. During the early stages of the production of an electronic board, the need often arises to have to make multiple versions of the same printed circuit board or simply to need to make a board consisting of several circuits.

0 kommentar(er)

0 kommentar(er)